About Us

A Family

BUSINESS

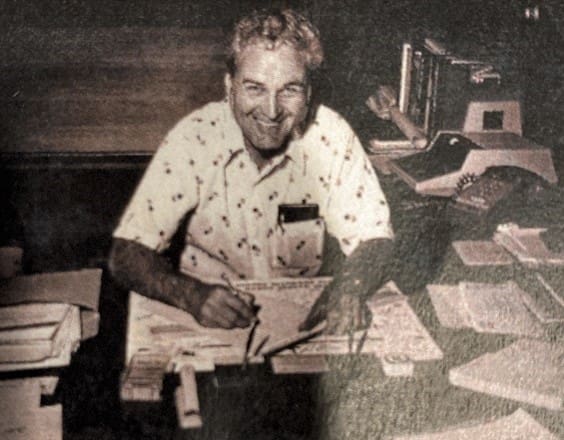

Edwards Cast Stone has been a family business since 1964, when Jim and Pat Edwards set out to build something lasting. Over the years, we’ve grown from a small construction company in the Midwest to a nationwide leader in cast stone manufacturing, operating out of our 44,000-square-foot, state-of-the-art facility.

What really makes us who we are, though, is our team. From design and planning to production and shipping, our talented and dedicated people work hard to deliver the highest-quality cast stone products — whether it’s standard pieces or custom castings in unique colors and designs.

We believe the best results come from collaboration, so we keep communication open every step of the way. That’s how we ensure your project runs smoothly and meets your vision.

For us, it’s not just about great products — it’s about great partnerships. And we’re proud to be a company you can trust,

job after job.

More than 90% of our work involves custom orders that are specifically designed to match the requirements of your unique project. While these products may take longer to create and cost more than standard ones, they are worth the investment. This is because each piece is carefully designed, shop drawings are precisely created and molds are made to ensure a one-of-a-kind installation that can be truly stunning.

Our expertly crafted cast stone is ideal for new construction and restoration. We work closely with architects to create custom molds, guaranteeing the new piece will match the existing stone. Our skilled team can produce wet and dry cast stone, and projects can include any combination of wet or dry cast pieces.

EDWARDS

DIFFERENCE

Precision is in our DNA, and we ensure that every step of our process reflects that. Our shop drawings are clear, accurate, and detailed to prevent mistakes before they happen, helping your project stay on track from the first stone to the last.

Our product’s durability goes beyond strength – it’s built for long-lasting performance. Through our sanding and etching process, each piece is crafted to withstand the elements while preserving its vibrant color and finish, ensuring reliability for today’s high-performance buildings.

In today’s fast-paced construction environment, timing is everything. We’ve built a reputation for delivering projects on schedule, with efficient palletizing and shipping that makes installation straight-forward and stress-free.

Trusted

Method

Collaborative.

We make the process smooth and seamless – right from the start. Our team works directly with yours to create clear, easy-to-understand shop drawings that eliminate confusion and reduce delays. Strategic planning drives successful execution.

Efficient.

Every detail matters. Our optimized palletizing and delivery system ensures your order arrives on time and in perfect condition. With every stone clearly marked and carefully organized, on-site installation is streamlined, eliminating unnecessary delays and reducing costs.

Innovative.

Our facility isn’t just state-of-the-art, it’s where the future of cast stone comes to life. We use the latest technology to enhance our craftsmanship, ensuring every piece is strong, durable, and ideally suited to modern design. The result? Products designed to impress.

Built to perform.

Meet Our Team